Production Introduction

Foundry

In the highly competitive manufacturing sector, Dingsheng Company maintains a leading position in the industry with its superb casting technology and innovative capabilities. The company has been in long-term cooperation with Bridgestone globally for over twenty years, serving domestic and international customers based on Bridgestone's technical quality requirements. It covers a diverse range of fields including automotive parts, engineering machinery components, agricultural machinery parts, train and railway accessories, as well as military products, meeting the diverse needs of global customers.

Main Equipment for Casting

Our factory is equipped with advanced production equipment and process lines, including a machining mold manufacturing workshop, a coating sand and resin sand workshop, a casting workshop (equipped with 3 one-ton furnaces, 1 0.5-ton furnace, and an 80-meter casting circulation line), a grinding workshop, a heat treatment workshop (3 mesh belt furnaces and 4 well-type furnaces), and a sandblasting workshop (one each of inclined, hanging, and crawler shot blasting machines). These facilities ensure the precision of products during the production process.

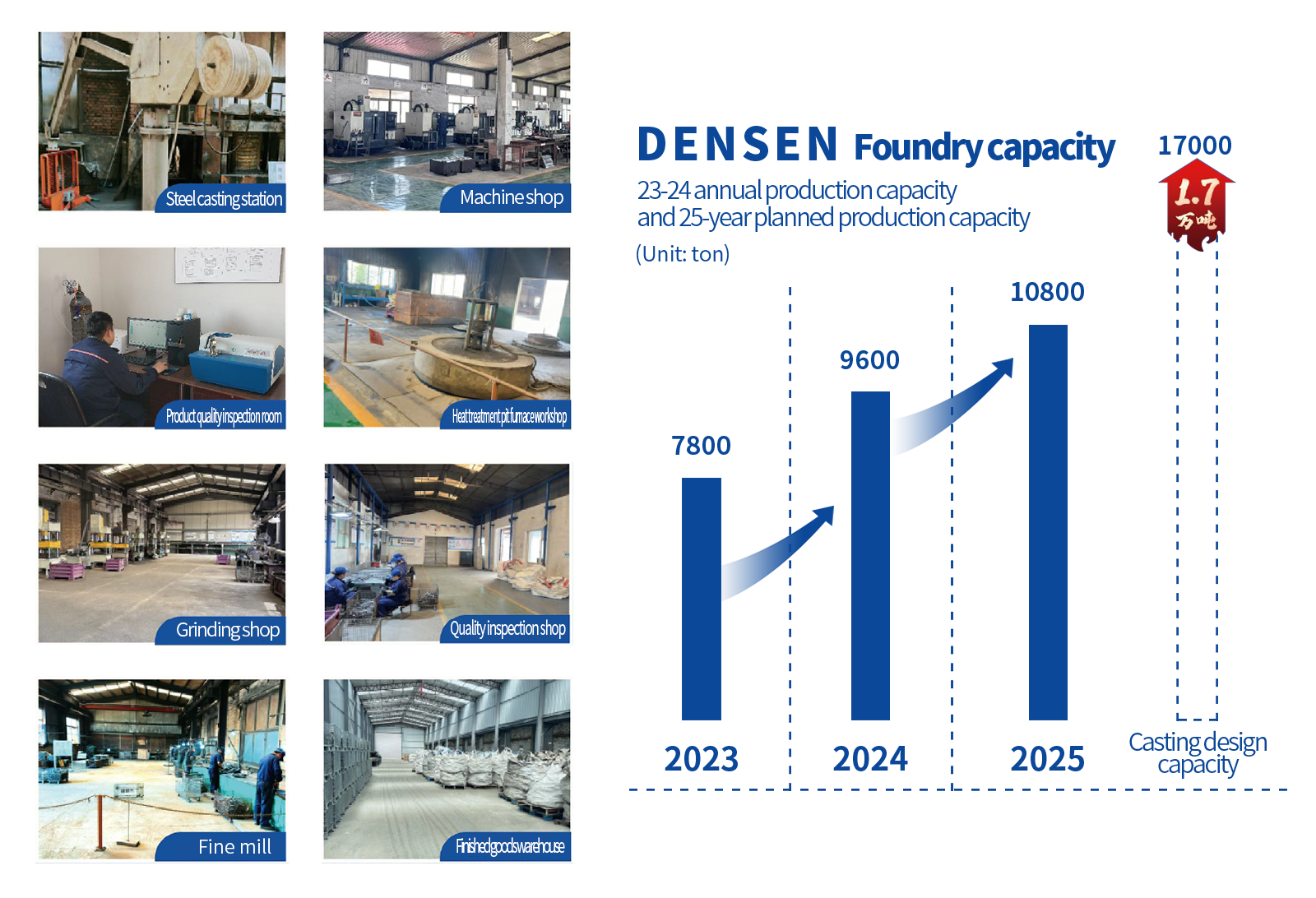

Casting Capacity Setting

Our foundry has a monthly design capacity of up to 1200 tons. Although the current actual monthly capacity can reach 600 tons, we are committed to continuously optimizing production processes and improving production efficiency, aiming to achieve and exceed the design capacity more quickly.

Types of Casting Products

Dingsheng Company focuses on the production of precision castings, with product weights ranging widely from 0.2 kg to 200 kg, meeting customer demands for various specifications. Our main product materials are: ductile iron, gray iron, and cast steel. All raw materials used are subject to strict quality verification, sourced directly from manufacturers, ensuring that each product possesses excellent mechanical properties and stable chemical composition.

Production Equipment

Production process

Casting weight range: 0.2 to 200 kilograms;

Main materials: ductile iron, cast iron, cast steel;

Product processes: coating sand process, resin sand process, steel membrane covering sand process.

Production environment and capacity

Basic Information and Advantages

Basic Information

Area: 20,000 square meters; Employees: 85; Monthly design capacity: 1,200 tons; Casting weight range: 0.2 to 200 kilograms.

Main materials: ductile iron, cast iron, cast steel; Product processes: coated sand process, resin sand process, steel membrane sand coating process.

Casting Advantages

▶ Implementing Japanese quality management system for over 20 years

▶ Pioneer in the development of casting core iron (iron teeth) for rubber track applications

▶ Team manufacturing experience of over 20 years