Production Introduction

Forging Factory

In the landscape of Dingsheng Company, the forging factory, with its superb technical strength and significant production capacity, has become another important engine driving industry progress. We focus on producing high-quality forged parts, widely used in automotive components, agricultural machinery, train and railway parts, military products, and other fields, meeting the diverse needs of global customers.

Main Equipment for Forging

The forging factory is equipped with cutting-edge production equipment, including automatic marking machines in the raw material cutting workshop and forging production lines. Among them, the forging workshop has heavy equipment such as a 5-ton hammer, a 2-ton hammer, a 1600-ton electric screw press, and 630 and 400-ton friction presses, capable of easily handling various complex forging process requirements. In terms of heating equipment, we use 5 medium-frequency furnaces and 2 box-type electric furnaces to ensure uniform and rapid heating of materials, providing stable heating products during the forging process. The heat treatment workshop is equipped with 2 sets of mesh belt furnaces and 2 well-type furnaces, optimizing the internal structure and performance of products through precise control of temperature and time; the sandblasters come in both inclined and crawler types to meet the surface treatment needs of different products.

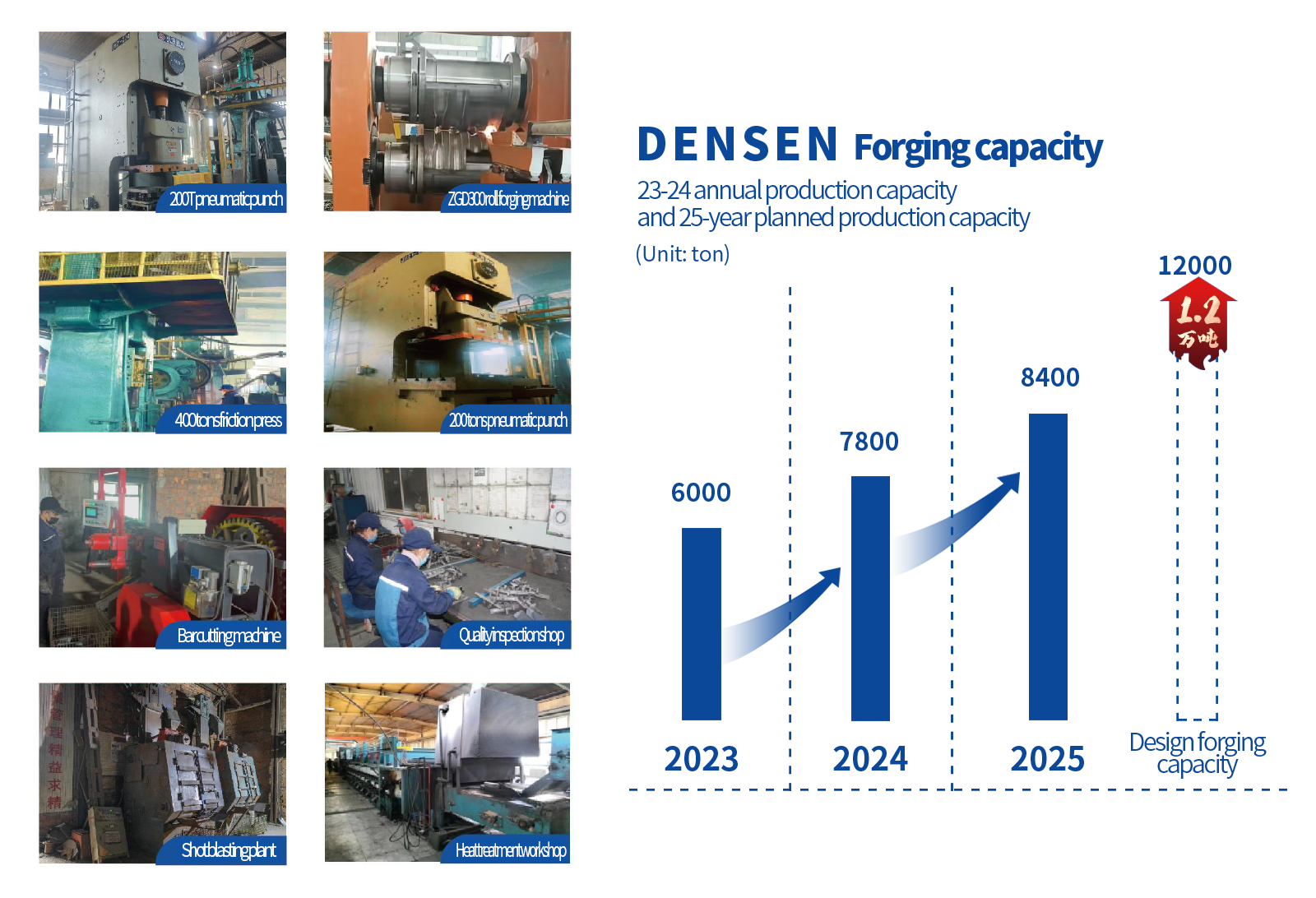

Forging Production Capacity Setting

Our forging factory has a monthly designed capacity of up to 800 tons. Although the current actual monthly capacity can reach 300 tons, we are committed to continuously optimizing production processes and improving production efficiency, aiming to reach and exceed the designed capacity more quickly.

Types of Forged Products

The weight of products that the forging factory can produce ranges from 0.3 kg to 30 kg, meeting customer demands for various specifications. Our forging factory mainly focuses on forged parts, and all the raw materials we use have undergone strict quality verification, with sources directly supplied by manufacturers, ensuring that each product possesses significant mechanical properties and stable chemical composition.

Production Equipment

Production process

Forging weight range: 0.3 to 30 kilograms;

Main material: round steel;

Product process: die forging hammer, friction pressure, rolling forging.

Production environment and capacity

Basic Information and Advantages

Basic Information

Area: 15,000 square meters; Employees: 50; Monthly design capacity: 700 tons; Forging weight range: 0.3 to 30 kilograms.

Main materials: Round steel; Product process: Die forging hammer, friction pressure, roll forging.

Casting Advantages

▶ Implementing Japanese quality management system for over 20 years ▶ The founder of the company has over 30 years of forging technology experience

▶ Team manufacturing experience of over 20 years ▶ The first company in China to procure forgings from Bridgestone globally